The test program consists of testing system in three steps:

startup, main test, and shutdown. After the program starts up and

reaches the steady state, each three hours reformate samples are

injected to GC which are identified by the code S1 to S15,

respectively. S1 to S15 are representative of a complete cycle of

catalyst in real industrial process.

After taking the last sample (S15), the shutdown process is

performed according to the program; in this point the catalyst is

deactivated and need to be regenerated.

Ilya perform regeneration and coke burning process of naphtha

reforming catalyst and finally catalyst will be regenerated and

ready to use in repeated test cycle. By do these steps and

investigations of the output results, customers will understand

the catalyst long term activity and stability.

So the Ilya pilot test provides conditions that every customer

will be able to find out its catalyst performance in terms of

operating and industrial scale clearly, accurately and with lowest

risk and cost to make the best choice.

At the end, the results of the tests will be reported separately

from each sample by accurately specifying the percentage and type

of hydrocarbons.

×

![]()

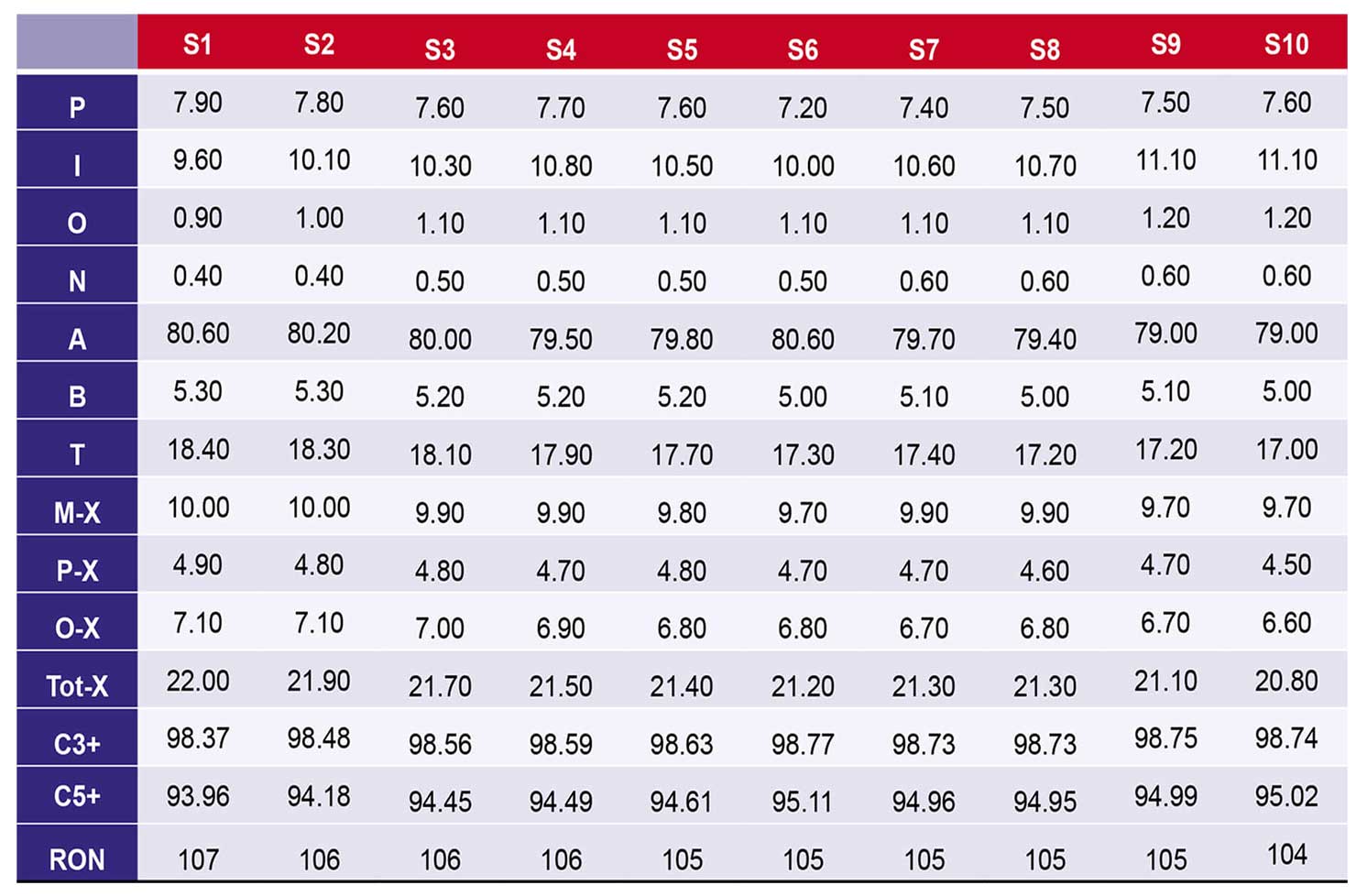

Sample Result

The figure relates to the test of naphtha reforming catalyst, which shows exactly the weight percent of Paraffns (P), I-Paraffns (I), Olefns (O), Napthenes (N), Aromatics (A), Benzene (B), Toluene (T), M-Xylene (M-X), P-Xylene (P-X), O-Xylene (O-X), the hydrocarbons higher than three carbons and five carbons in 15 samples of each product.

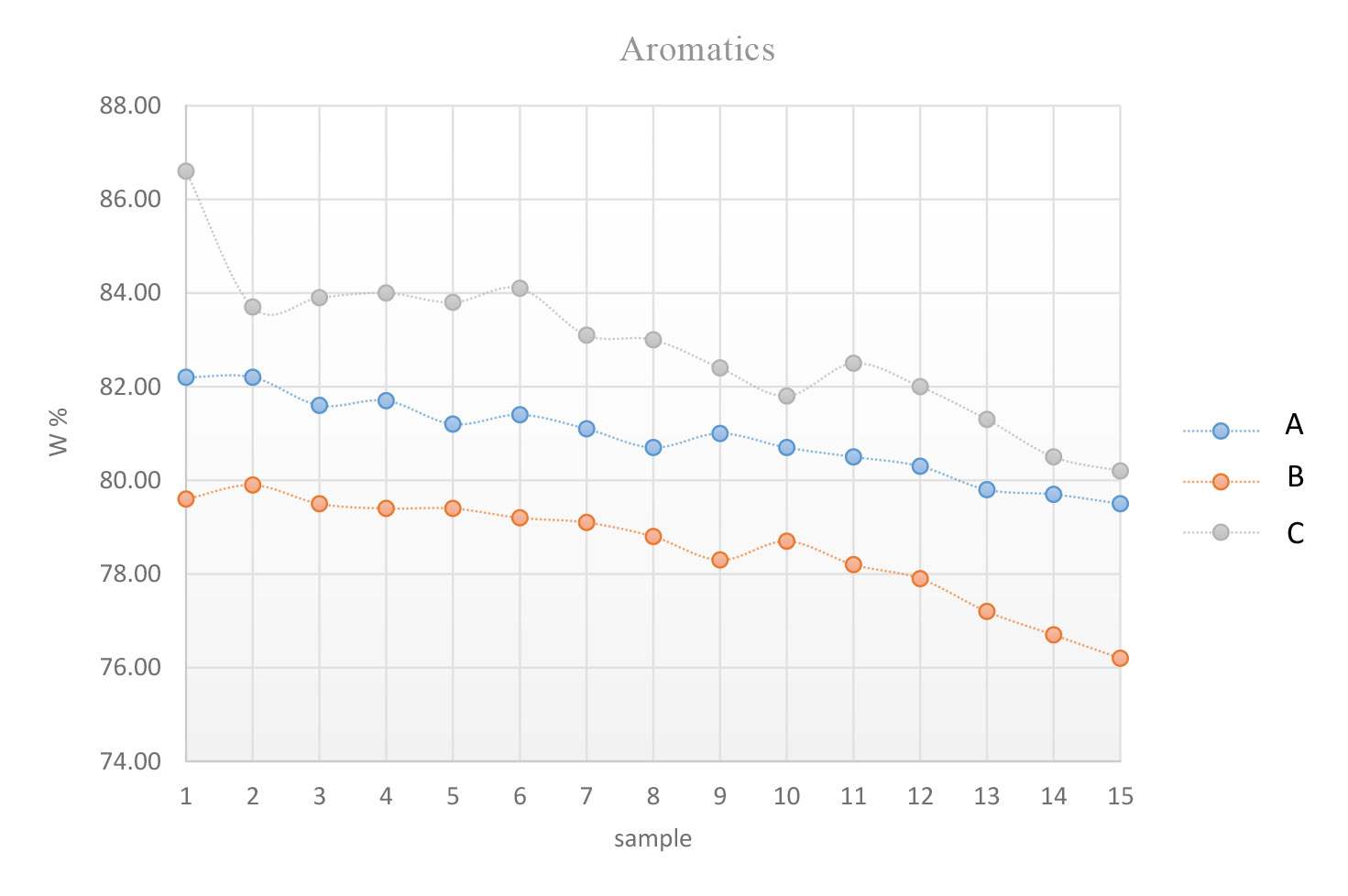

Aromatics

This diagram relates to the test of three different catalyst types, A (one of the pioneer catalyst in market), B and C (Ilya catlysts), which shows the total weight percentage of the aromatic produced in 15 samples of each product.

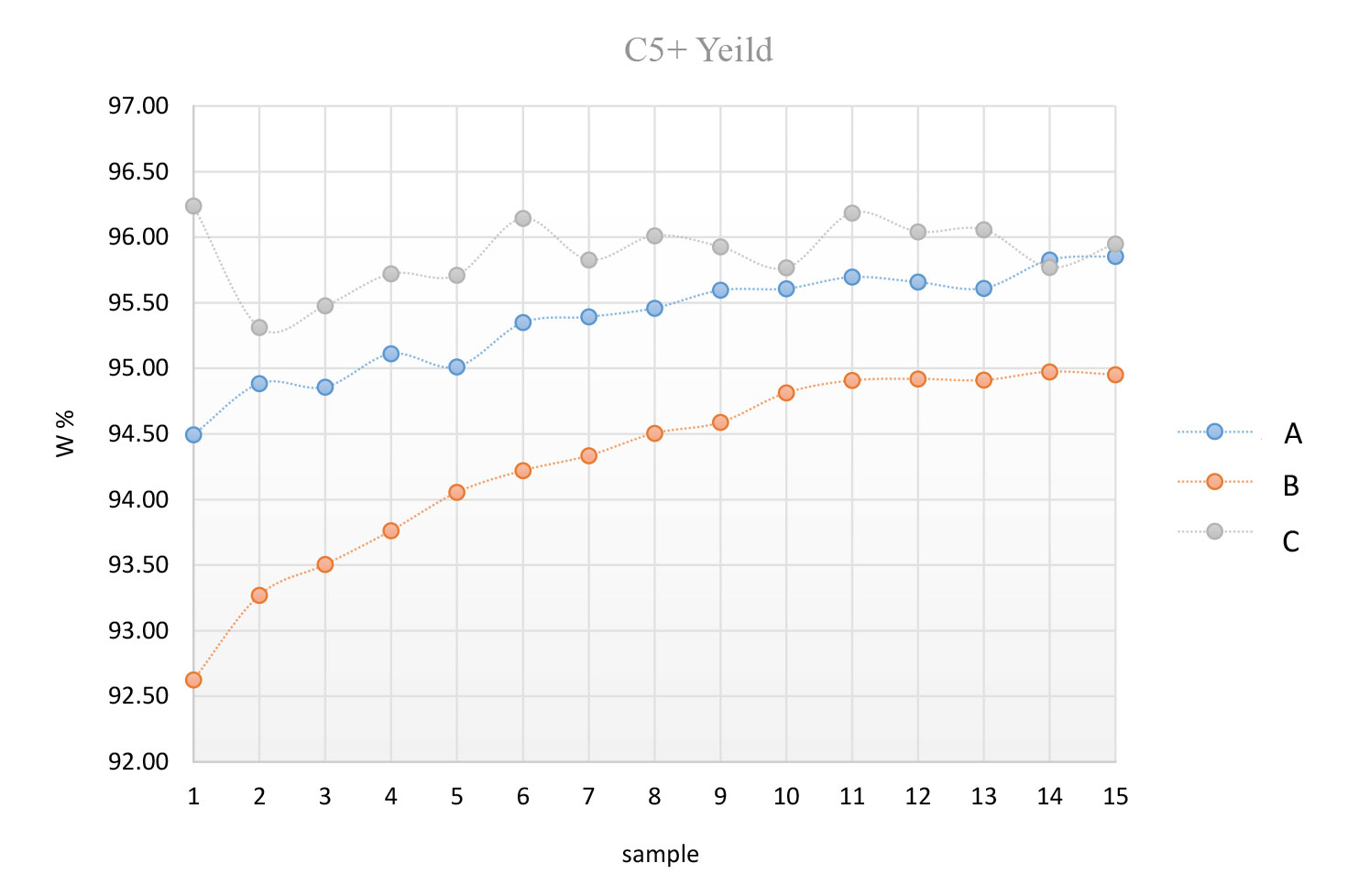

C+5 Yield

The figure relates to the test of three different catalyst types, A (one of the pioneer catalyst in market), B and C (Ilya catlysts), which shows the weight percent of refined produced on the basis of five carbons and more in 15 samples of each product.

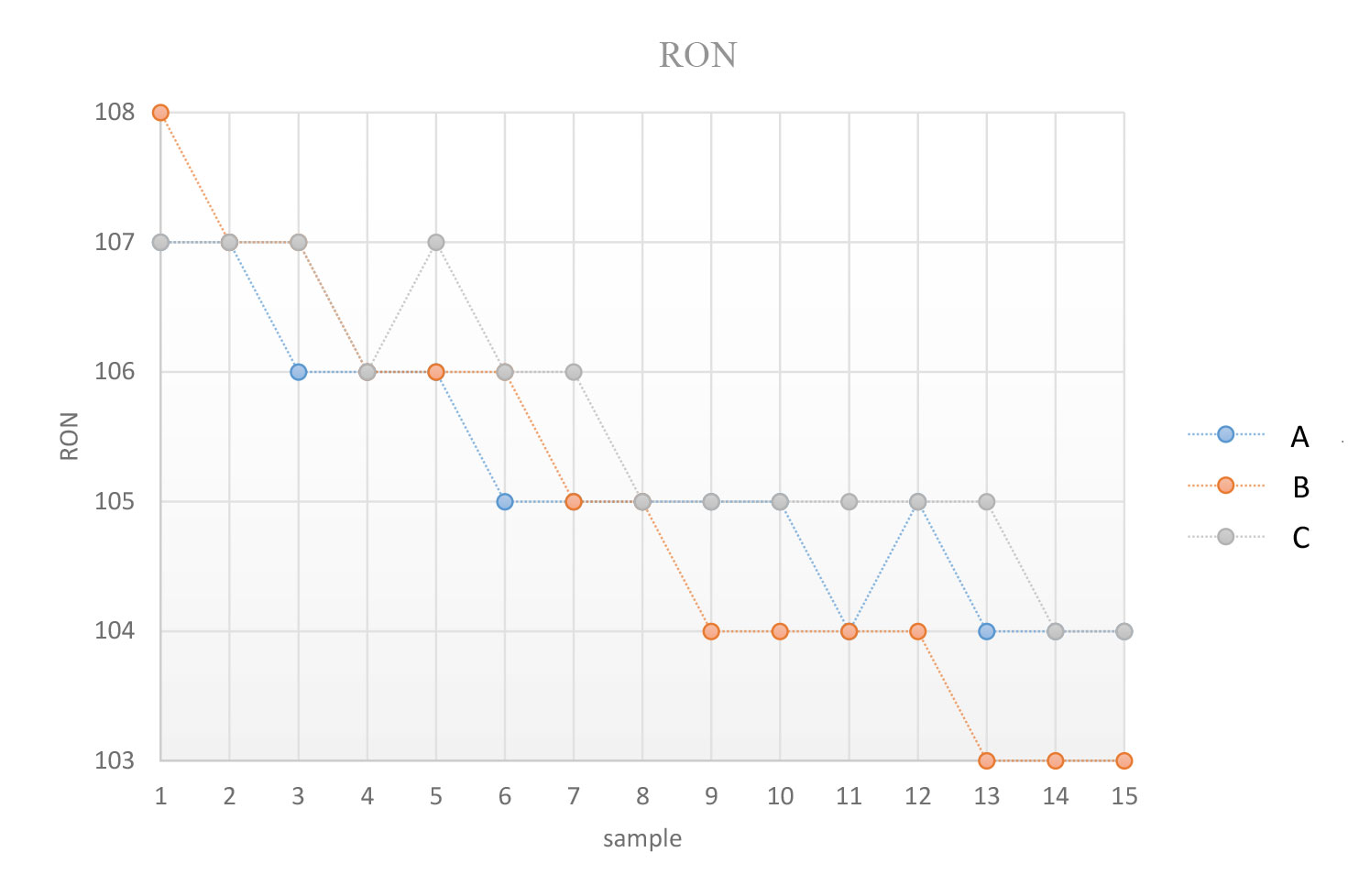

RON

This diagram relates to the test of three different catalyst types A (one of the pioneer catalyst in market), B and C

(Ilya catlysts), which shows clearly the octane number of 15 samples of each product.