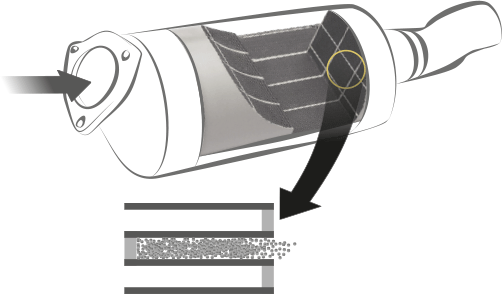

Diesel particulate filter DPF

Nowadays, as response to air pollutants concentration increase in atmosphere because of transportation and industrial activities, some different technology has been developed to reduce and control air pollutants emission. One of the most harmful air pollutants is Particulate Matter (PM) in which causes some dangerous illness like cardiovascular disease and Respiratory disease. DPF (diesel particulate filter) is one of the most effective technologies that reduces PM emission up to 99.9 percent.